Smelting/Recycling

Low carbon technologies

We develop processes for the secondary resources value chain.

Zero waste technologies

We are also developing refining processes for nickel sulphide materials.

New product development

New Energy Materials

PUSHING BACK THE LIMIT OF CURRENT MATERIALS

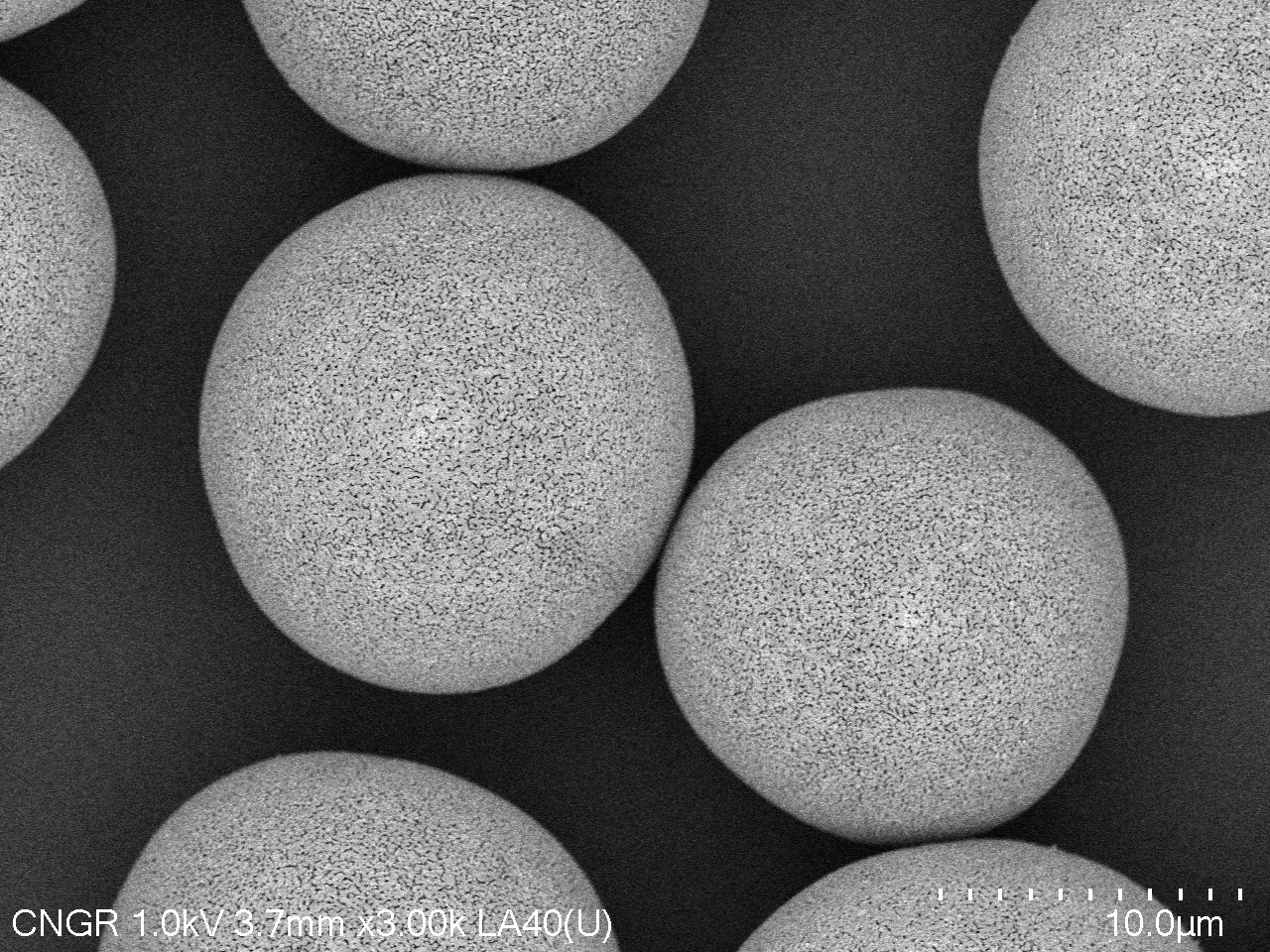

Cobalt-free Single-Crystal technology:

We are developing innovative precursors for cobalt-free cathodes with the aim of significant cost reduction.

For the first time, the industry was moving into single-crystal Co-free technology mass production.

High-voltage Single-Crystal technology:

CNGR’s successful R&D efforts have improved the performance of the small particle medium-nickel precursor for high-voltage cathodes and enabled it to enter the mass production phase.

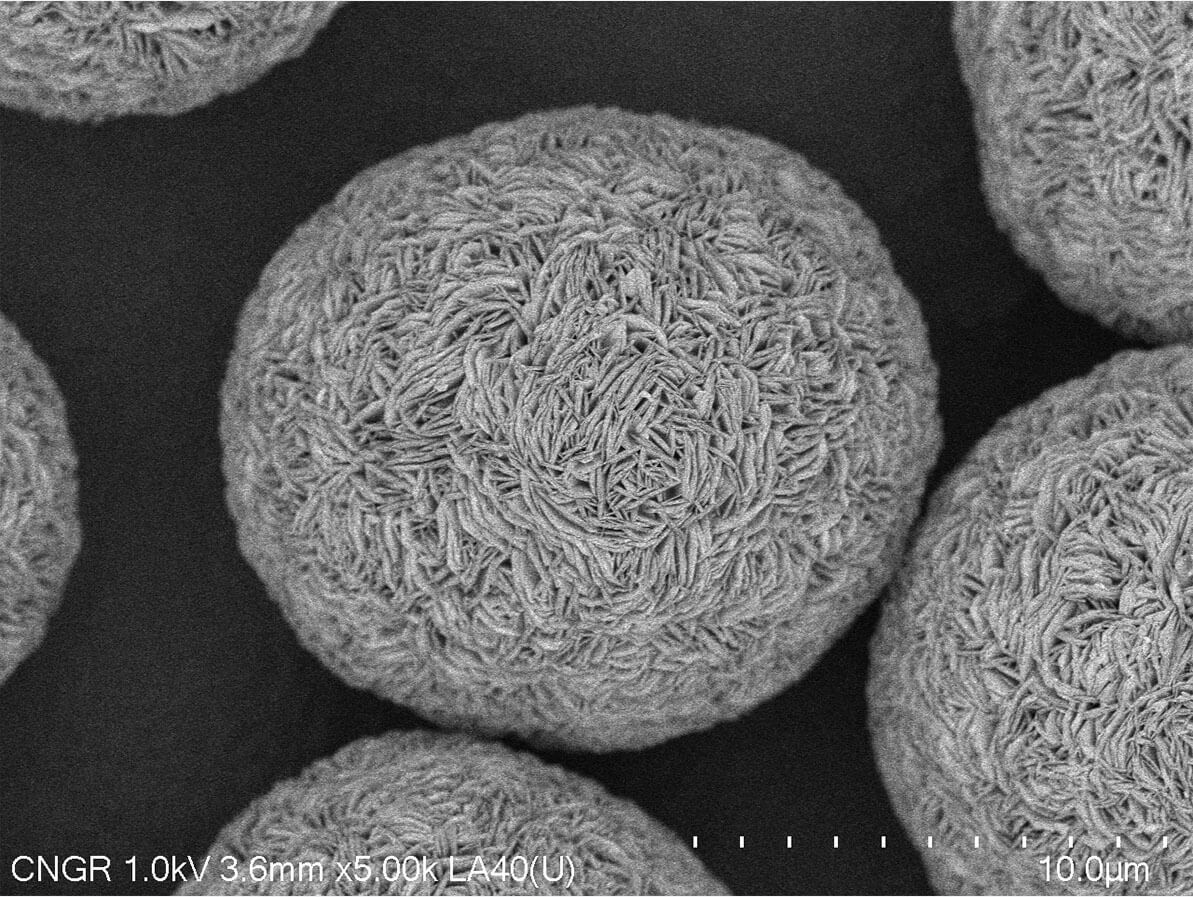

Ultra-high nickel technology:

We continue to make breakthroughs in Ni95 and above precursor materials, including improvements in structure and crystallinity.

We have entered the mass production phase with a focus on capacity and rate capability.

The technical challenge of reduced cycle performance and energy density of lithium cobalt oxide at high voltage has been overcome.

Enhanced tricobalt tetroxide uses uniform doping technology to increase the voltage of lithium cobalt oxide to 4,53 V, enabling it to now enter the mass production.

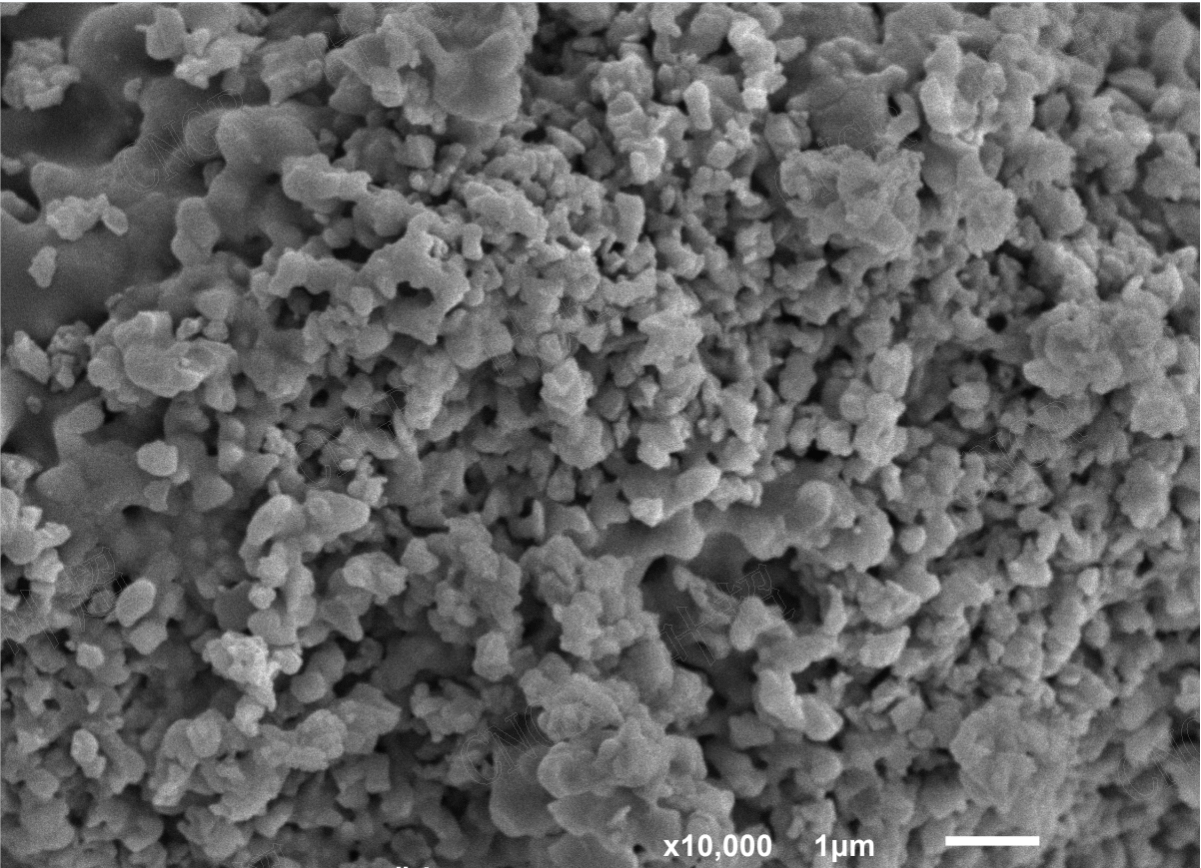

Improved lithium iron phosphate (LFP) technology:

7% cost reduction over conventional technology.

Lithium iron phosphate fromphosphate ore:

Low cost and high performance LFP cathode.

Controlled co-precipitation to produce homogeneous iron manganese phosphate precursor, and subsequently lithium iron manganese phosphate (LFMP):

Low cost, high product consistency and superior overall performance LFMP cathode.

The substitution of sodium for lithium in the sodium-ion battery is to be welcomed in order to better allocate critical mineral resources. This emerging technology is beginning to enter the market for energy storage and certain electric vehicles. To support its customers, CNGR has already started to supply materials for sodium-ion batteries on an industrial scale.

Ecology and safety

CNGR’s industrial chain includes the smelting of raw ores, the refining of raw materials, the preparation of precursor cathode active materials and the valorisation of resources through recycling to achieve a green cycle and low carbon development.

CNGR is engaged in Continuous Improvement Process, integrating advanced production equipment and its automation, to create low-carbon production lines with improved safety performance.

High performance

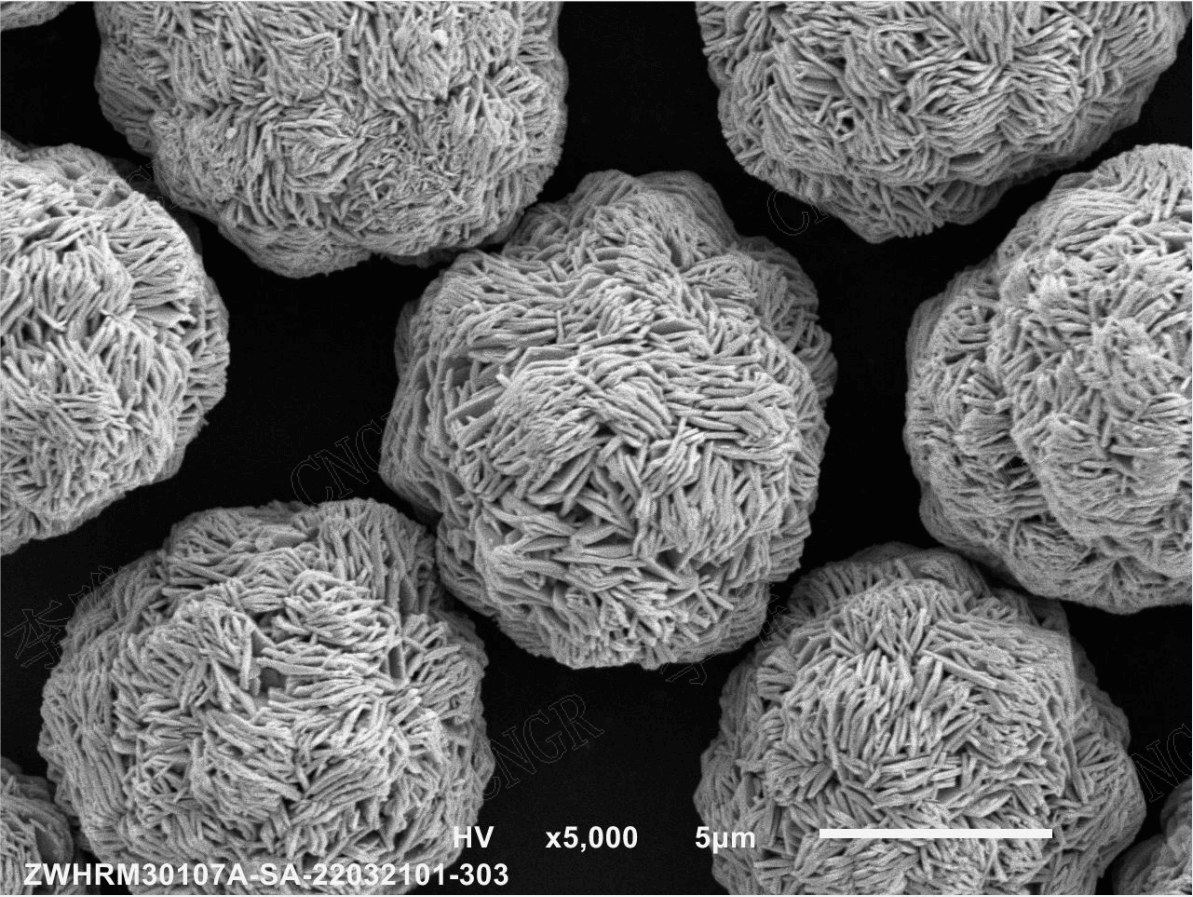

Thanks to our in-depth knowledge of the co-precipitation mechanism, the nucleation rate and growth rate of the precursor are precisely and judiciously controlled.

The structure of the precursor and the crystalline orientation of the particles are optimised to enable the product to achieve higher capacity and improved cycling capability, enabling the production of batteries with longer life.

Intelligent and innovation

We have integrated systems + AI research and development, using intelligent computing, intelligent transmission and data collection.

We have shortened the research and development cycle, helping customers to achieve more efficient development.

Environmental protection

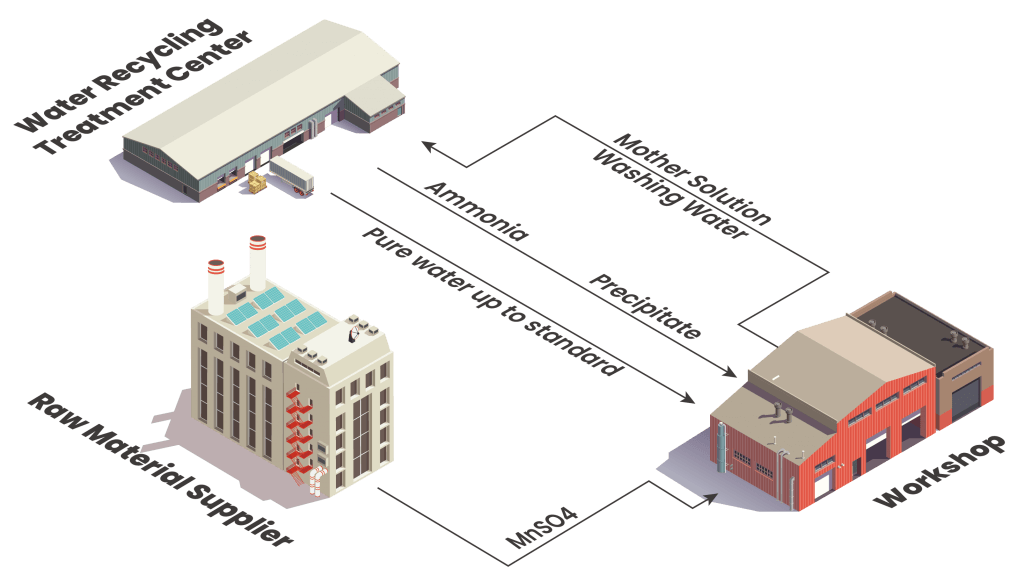

Waste Water and Solid Waste Recycling

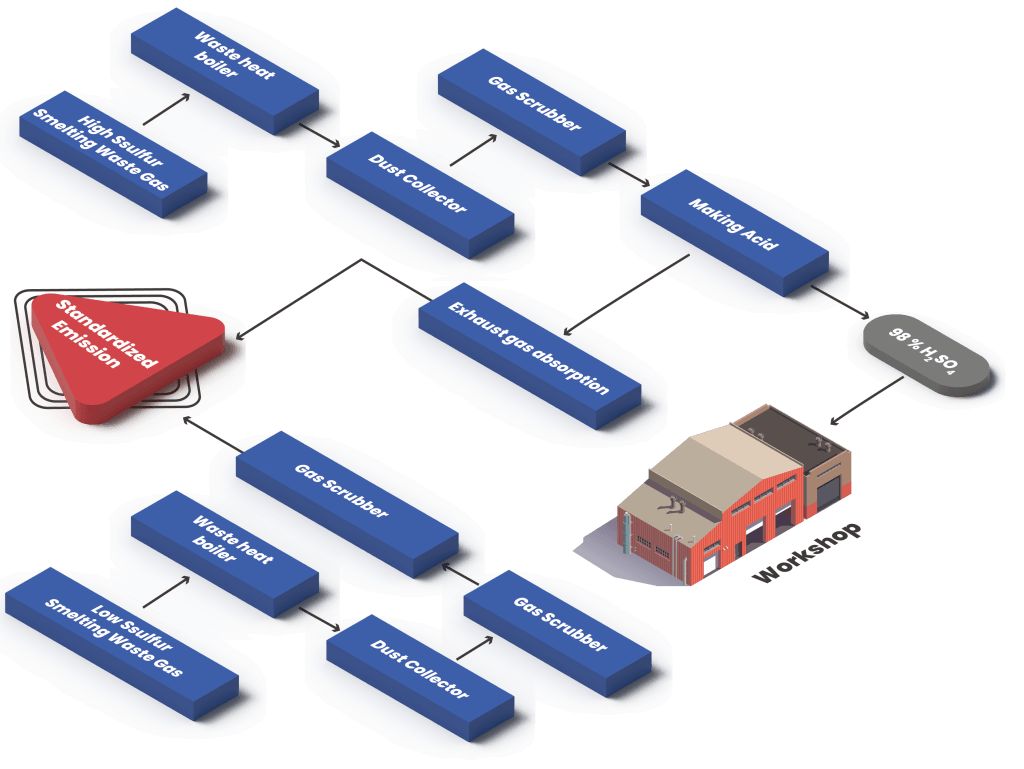

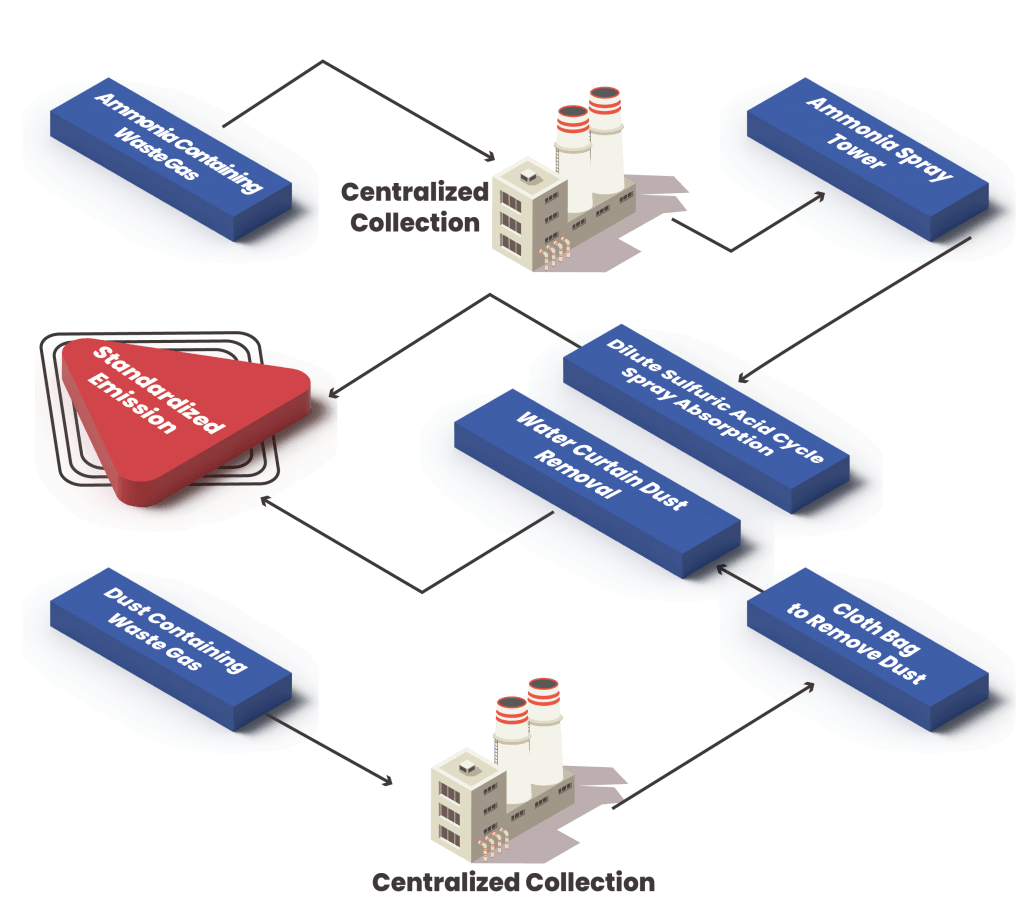

Waste Gas Recycling

Smelting/Refinery Waste Gas Recycling