Lithium batteries recycling : a closed loop

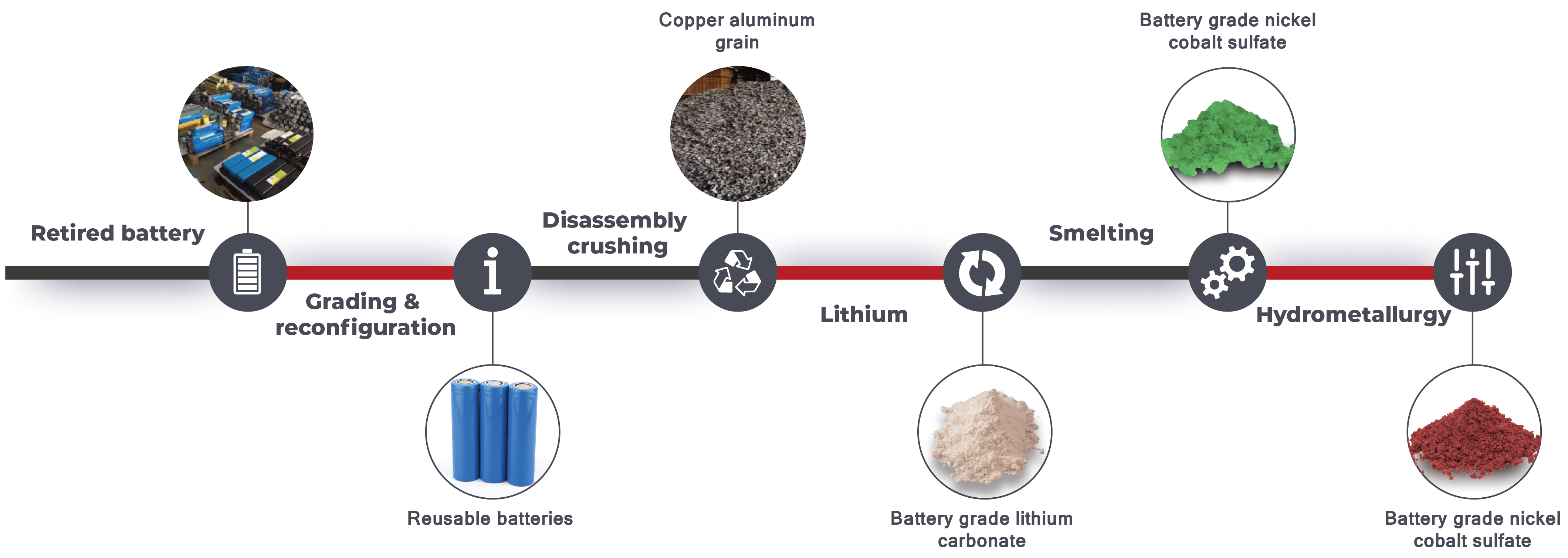

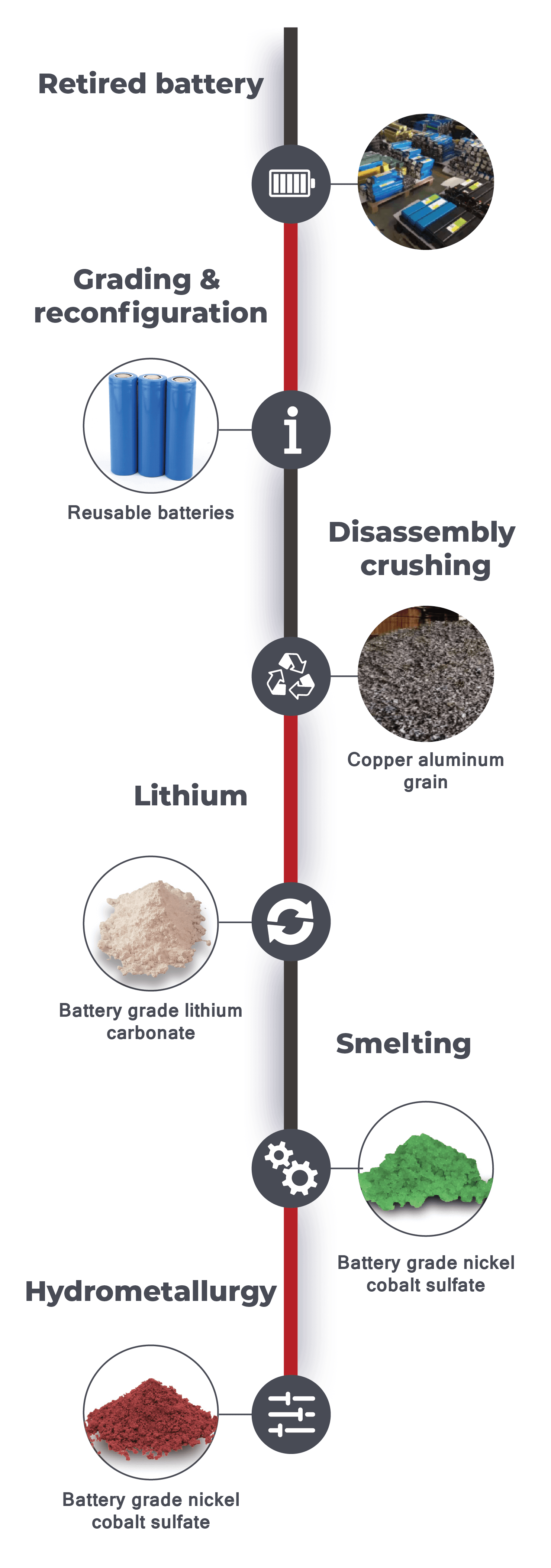

Timeline of CNGR’s recycling activities:

Through the recycling of lithium-ion batteries, CNGR reuses valuable elements such as cobalt, nickel or lithium.

The black mass recovered from battery recycling allows CNGR not only to ensure a sustainable supply of essential raw materials in the production of lithium batteries, but also permits a reduction in the negative impact of lithium batteries on the environment.

CNGR expertise and advanced technology allow CNGR to actively participate in all recycling steps from diagnosis to post-treatment.

Types of recycled products

Advantages of recycling technology

High level of automation

Through a visual recognition system, we get a precise position of pieces and optimize disassembling. We combine a high degree of diversification and standardization at the different stages. On this basis we can rely on automation and strong compatibility. This enables us to handle mainstream models of battery packs and modules in the market.

Industrial design is green and harmless

The production line is designed with charged crushing, electrolyte recycling, tail gas treatment and other devices to reduce the output of hazardous waste.

High metal recovery rate

When advanced recovery technology is adopted, the recovery rate of lithium metal gradually reaches more than 90%, and the recovery rate of nickel and cobalt metal is expected to eventually reach more than 98%. Such a rate contributes to sustainability and better profitablility.

Reducing operating costs

By recycling lithium batteries and reusing dismantled elements such as nickel parts and powders we recover valuable materials like nickel sulphate or cobalt sulphate. This allows us to reduce our production costs.

Mitigating environmental impacts

By continuously expanding into the recycling industry, CNGR plays an important role in mitigating the environmental impact of lithium batteries. Thus, batteries help to reduce the company’s carbon footprint.

Global recycling business distribution

CNGR built and put into operation the first waste battery recycling production line in Tongren, Guizhou Province, China in April 2021, achieving 25,000 tons of nickel-cobalt metal smelting and comprehensive recycling capacity per year.

Based in Frankfurt, the headquarters of our recycling division coordinates projects located both in North America and Europe.