Comprehensive supplier of precursor cathode active materials (pCAM) to the battery industry

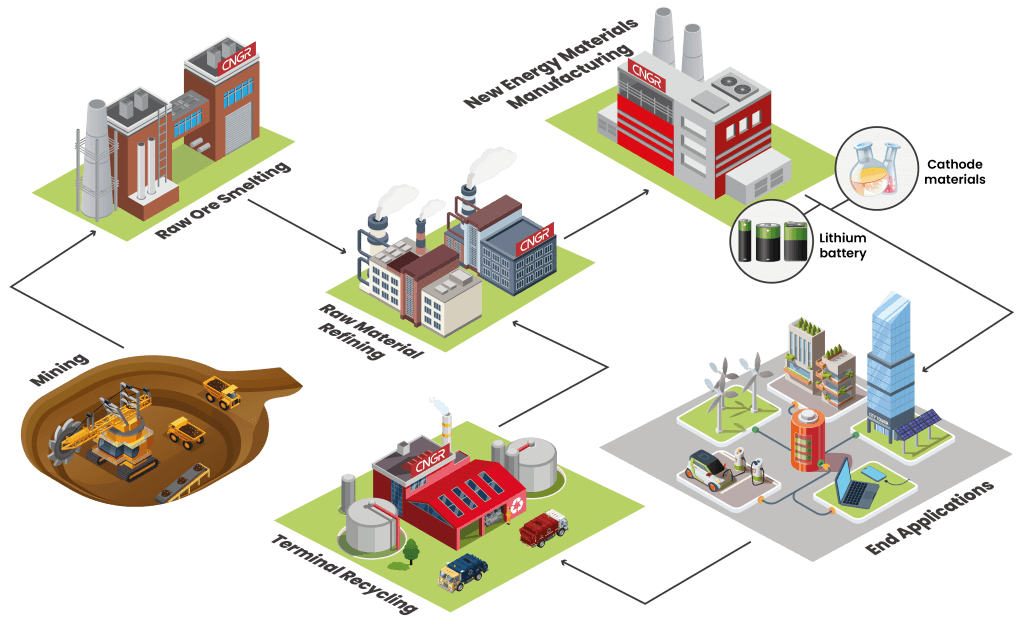

Stabilising raw material supplies

Sudden and large increases in demand can lead to imbalances in the supply of raw materials. To achieve an independent, predictable and stable raw material supply, CNGR has established a closed-loop integrated industrial chain of “raw ore smelting — raw material refining — pCAM production — recycling”.

Cost control

Raw materials used to produce precursors account for more than 90% of operating costs. CNGR can better control costs and be more competitive by controlling the entire process.

Recycling of used batteries

Through mutually beneficial cooperation with domestic and overseas enterprises, CNGR has established a global recycling industrial chain for used batteries with a complete recycling technology platform. This powerful technology reduces the environmental impact of used batteries and supports our customers’ efforts to meet increasingly stringent regulatory requirements.

Material products

CNGR is committed to diversifying, customising and rapidly expanding the mass production of cathode precursor active materials and related technical and industrial service capabilities. By implementing a technology diversification strategy, CNGR has achieved full coverage and mass production of pCAM materials comprising nickel, cobalt, phosphorus and those related to sodium-ion battery.

There are currently four main leading product families, namely high voltage tricobalt tetraoxide, ternary precursors (NCA and NMC precursors), iron phosphate and for sodium-ion battery, sodium precursors and sodium-ion cathode materials.

These products play an essential role in the manufacturing process of cathode materials and are widely used in electric vehicles (PHEV and EV), consumer electronics (3C market) and energy storage systems (ESS). The sodium-ion battery is a newer technology that is beginning to emerge for energy storage and some electric vehicles.

Full range of ternary precursors

Precursor for NCM & NCA battery

Lorem

Performance characteristics

High safety

High energy density

Long life cycle

Application area

Electric Vehicules (EV)

Battery Energy Storage (BES)

High voltage tricobalt tetraoxide

The precursor for lithium cobalt oxide (LCO) battery

Performance characteristics

High voltage

High power

High power

Application area

Consumer electronics (3C)

Sodium-ion precursors

Precursor cathode active material & cathode for sodium-ion battery

Performance characteristics

Long life cycle

High safety

High rate

Application area

Battery Energy Storage (BES)

Electric Vehicles (EV)

Iron phosphate

The precursor for lithium iron phosphate (LFP) battery

Performance characteristics

Long life cycle

Thermal stability

Cost effective

Application area

Electric Vehicles (EV)

Battery Energy Storage (BES)

Raw material products

Nickel related products

Nickel sulfate (NiSO4)

Mainly used for electroplating, nickel battery, catalyst and production of other nickel salts, also used for printing and dyeing agents, metal colouring agents, etc.

Electrolytic nickel (Ni)

Electrolytic nickel is mainly used in nuclear energy industry, alkaline battery, electrical alloy, high temperature and high strength alloy, catalyst and powder metallurgy additive, diamond tools, non-iron based alloy and hydrogenation catalyst for organic synthesis.

Cobalt intermediate products

Cobalt sulphate (CoSO4•7H20)

Used in the manufacture of cobalt salts, paint desiccant, cobalt pigments, alkaline battery additives and electroplating.

Cobalt chloride (CoCI2•6H20)

It is mainly used as paint desiccant, ammonia gas absorption, dry and wet indicator, electroplating, ceramic colouring agent and medical reagent.

CNGR partners

The infographic below illustrates the principal partners that use CNGR’s two main industrial products (ternary precursors and tricobalt tetraoxide) for the production of cathode active materials and as end users in batteries.

Customers benefits

As an agile company, CNGR is actively contributing to the development of the global advanced battery industry by constantly adapting to the needs of key market players and accelerating its international expansion.

CNGR has become a trusted partner to many leading manufacturers in the battery value chain and its products are an integral part of their supply chain.

logo 1

logo 2

logo 3

logo 4

logo 5

logo 10

logo 9

logo 8

logo 7

logo 6

logo 15

logo 14

logo 13

logo 12

logo 11

logo 20

logo 19

logo 18

logo 17

logo 16